Airflow is critical to heat distribution, fuel efficiency, and site safety on construction jobs. While we presented these and other benefits in previous posts (reference previous posts in a call out), this post highlights three creative ways Babfar customers have used airflow to their advantage.

Trash Chutes

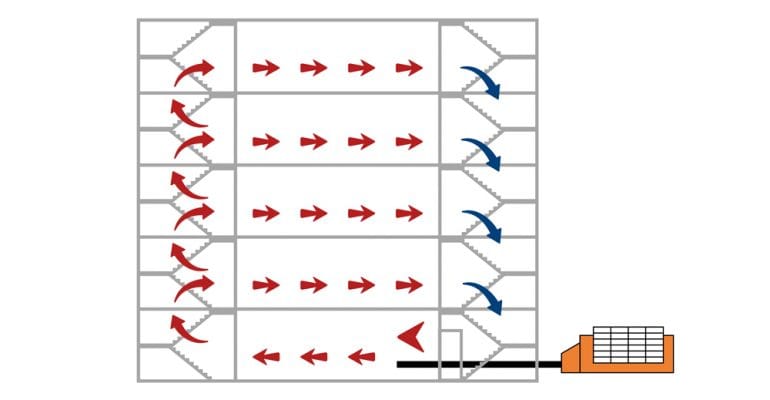

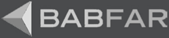

One clever customer has a unique way distributing heat effectively in high-rise buildings without using ductwork: permanent trash chutes.Typically trash chutes are steel or fiberglass and make perfect ventilation systems. Depending on the footplate, a job may have several chutes. So, why not use them? Our customer adjusted the schedule to finish the chutes later in the project. This just meant postponing the electrical work.Ductwork wasn’t even needed to distribute heat through the chutes. By simply forcing hot air into the structure at ground level, passive airflow took care of the rest. Hot air rose through the chutes. Openings on each floor allowed air to exhaust from the building. The resulting air circulation evenly distributed heat.Stove VentsAnother clever customer was faced with the challenge of heating five townhouses, each with nine apartments. Renting temporary heaters for 45 units was not practical. Running ductwork to apartment windows was going to be difficult and costly. The solution? Stove vents.With a single trunk line and multiple risers, the contractor forced hot air backward through the network of ducts to stove vents in each unit’s kitchen. A single heater at the end of each townhouse successfully heated each of the nine apartments.Using positive pressurization, the customer filled each townhouse with hot air. Cold air was forced into stairwells and down to the ground level before exiting the building through common entryways. Workers entering and exiting the building helped to ensure an air change and heat distribution.Stairwell Pressurization SystemsDuring the first season of the Millennium Tower construction, a customer successfully heated the lower half of the 60-story building from the ground level using passive airflow. Unfortunately, this approach was not going to work for the upper-half the following season.Initially, they planned to place heaters on every other floor. They quickly realized this would be extremely expensive. In addition to the cost of renting and running multiple heaters, it would cost $5k to $10k to install and remove each of the units.So, it was time to get creative. Working with Babfar, they decided to use the building’s stairwell pressurization system. The ventilation system, designed to manage smoke during a fire evacuation, was used to heat the building during construction. We placed two units on the roof. Grates located on every third floor distributed heat to the top 30 stories.Knowing that the crane would not be available at the project’s completion to remove the temporary heaters, we planned to dismantle them. Salvaging and scrapping the heaters, believe it or not, was more cost-effective than placing heaters on individual floors.Babfar temporary heaters are designed to provide high cubic feet per minute (CFM) output. This allows the units to overcome static pressure, generate airflow and distribute heat in these examples.Our customers always look for creative and effective ways to distribute heat. Babfar reps also help by reviewing plans and walking through sites to find opportunities to use common areas as fresh-air plenums and distribute heat. Trash chutes, stairwells, elevator shafts, and stove vents are just a few examples of how Babfar customers distribute heat, ensure an air exchange and save on fuel costs.

Babfar

This information box about the author only appears if the author has biographical information. Otherwise there is not author box shown. Follow YOOtheme on

Twitter or read the

blog.